Welds

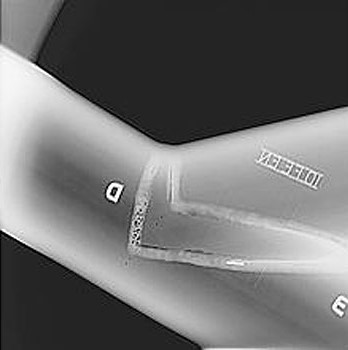

Weld inspection using digital X-ray is a state-of-the-art and effective method for quality assurance of aluminum welds. Thanks to the advanced X-ray technology, we can precisely x-ray the inside of the welded joint and detect potential defects or irregularities. This allows for a thorough examination of the aluminum welds to ensure that they meet strict quality standards. Digital X-ray inspection provides a fast and reliable solution to ensure outstanding weld quality and improve the safety and durability of aluminum components.

EN ISO 17636-2:2013: This standard specifies the requirements for non-destructive testing of welded joints in aluminum and its alloys using X-rays.

EN ISO 9712:2012: This standard specifies the requirements for the qualification and certification of personnel performing non-destructive testing, including X-ray testing.

ASTM E1742-18: Standard Practice for Radiographic Examination: This ASTM standard describes general procedures for radiography, including X-ray inspection of welded joints in aluminum.

AWS D1.2/D1.2M: Structural Welding Code – Aluminum: This American Welding Society (AWS) standard contains requirements and procedures for welding aluminum and aluminum alloys.

ISO 11666:2008: Non-destructive testing of welds – Ultrasonic testing – Acceptance levels: Although this is not a specific standard for X-ray inspection, it can be used as a reference for the acceptance criteria in the evaluation of welds.

Create a list

Sorting the X-rays

Tailor-made service

Try our X-ray inspection service!

Revealing precision: Where technology and expertise come together for flawless quality!