Electronics

Especially during soldering processes, air pockets often occur, which can affect the contacts. Fractures may occur or heat may not be sufficiently transferred. With the help of X-ray technology, we can determine exactly how much of the area of the solder pad is actually connected to your component. Often, the copper layer of the board should contribute sufficiently to the cooling of the IC, but if there is an insulation layer due to poor soldering, it will have a negative effect. Particularly problematic is the fact that the air expands as soon as the component heats up, which can lead to microcracks in the foreseeable future. With our X-ray inspections, we can detect these potential problems at an early stage and optimize your solder joints.

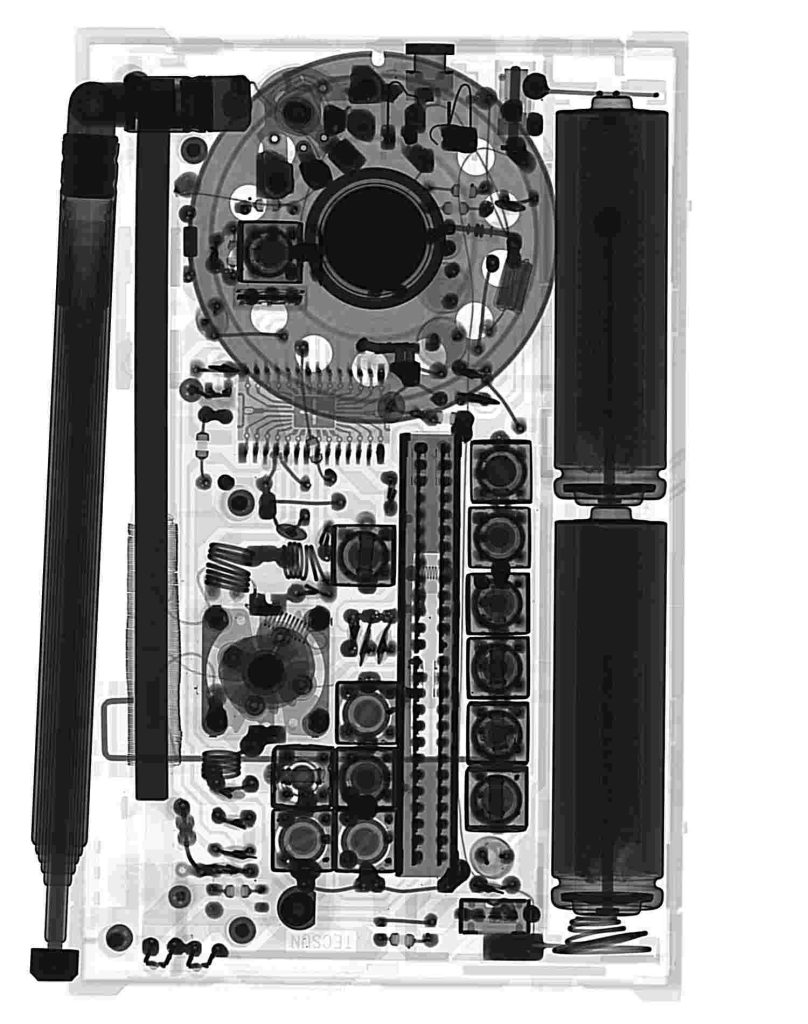

Discover the fascinating world of non-destructive X-ray testing for electrical switches, emergency stop switches and other components. Thanks to our state-of-the-art X-ray technology, you can see the internal movements of these components live in the video. We trigger the switch, allowing you to get detailed insights into how it works. Our creative team can trigger not only electrical but also mechanical switches to provide you with a comprehensive inspection of your components. Rely on our experience and expertise in X-ray inspection to ensure the quality and safety of your electrical components.

Create a list

Sorting the X-rays

Tailor-made service

Try our X-ray inspection service!

Revealing precision: Where technology and expertise come together for flawless quality!