Aluminium

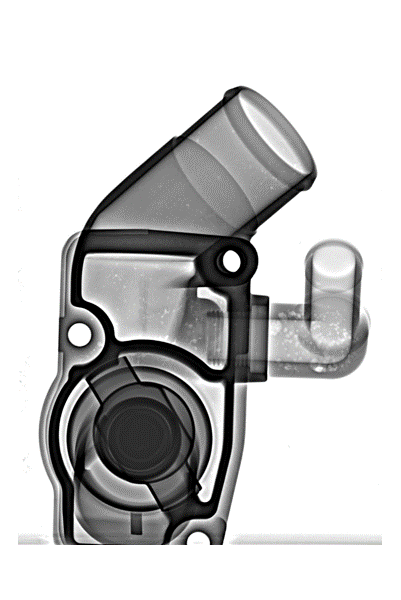

Aluminum X-ray is commonly used to detect cavities, pores, air pockets, thread voids, or cracks in permanent mold casting, sand casting, or die casting.

Defects can also be found in continuous casting.

Common material thicknesses are in the range of 1 to 100 mm. X-ray voltages from 100 kV to 200 kV are typical.

An evaluation according to ASTM E505 is no problem. Aluminum castings are often inspected in large quantities. We create lists for you and sort X-rays and data in such a way that you as a customer receive the relevant information clearly.

Our aluminum X-ray service allows you to verify the quality and integrity of your castings and ensure they meet the required standards. If necessary, we adapt the X-ray inspection specifically to your requirements in order to provide you with the best possible results. Feel free to contact us for more information about our aluminum X-ray service and how we can help you with the quality control of your aluminum castings.

Create a list