Magnesium

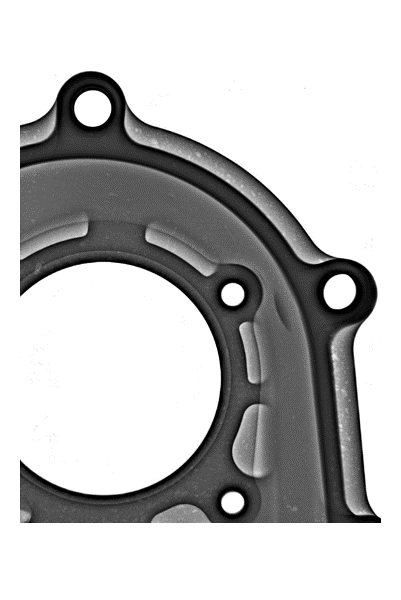

X-rays of magnesium are commonly used to detect cavities, pores, air pockets, thread voids, or cracks in magnesium parts that have been produced by casting, forging, or extrusion. Defects can also be identified in the production of magnesium die-cast parts.

The material thicknesses of the magnesium parts to be tested can vary and typically range from 1 to 50 mm. X-ray voltages from 50 kV to 150 kV are common for accurate radiography of the magnesium parts.

Magnesium alloys are particularly common, which contain proportions of aluminum, zinc and manganese in addition to magnesium. These alloys are used in many applications, including aerospace components, automotive components, housings for electronic devices, and sports equipment.

An evaluation according to ASTM is common in the X-ray inspection of magnesium and allows a reliable assessment of the quality.

Our experienced experts create detailed lists and carefully sorted X-ray images and data for you so that you as a customer receive the relevant information clearly. With our magnesium X-ray service, you can ensure that your magnesium parts meet the high standards of your industry and are free of structural defects.

If necessary, we adapt the X-ray inspection specifically to your individual requirements in order to provide you with the best possible results.

Do not hesitate to contact us for more information about our magnesium X-ray service and to support your quality control of magnesium parts.

Create a list